ULTRASONIC FLOWMETERS

Versatile and economical flow measurement of gases and liquids up to a nominal diameter DN 4000. Using ultrasonic waves, the flow volume of a wide variety of gases and liquids can be measured reliably – independent of electrical conductivity, pressure, temperature or viscosity. In applications that require traceable and guaranteed accuracy, inline ultrasonic sensors are preferred for use. Clamp-on ultrasonic sensors, on the other hand, are installed on the outer wall of the pipe and thus also enable temporary measurements or a retrofitting.

Read MoreCoriolis Mass Flowmeters

Simultaneous measurement of mass flow, density and temperature opens up entirely new perspectives for process control, quality assurance and plant safety. Additional important characteristic values can also be calculated from the primary variables measured:

- Volume flow

- Solids content in a fluid

- Concentrations in multiple-phase fluids

- Special density values such as reference density, °Brix,°Baumé, °API, °Balling, °Plato, etc

Electromagnetic Flowmeters

Proven flow measuring technology for all electrically conductive liquids in every industry Electromagnetic flowmeters have been used throughout industries for more than 60 years.

These meters are applicable for all conductive liquids, such as water, acids, alkalis, slurries and many others. Typical applications are monitoring of liquids, filling, dosing and precise measurement in custody transfer.

The two million magmeters we’ve sold since 1977 need no maintenance and offer seamless system integration into your processes.

Read MoreVortex Flowmeters

Vortex flow measurement: Robust and universally applicable for liquids, gases and steam.

Vortex flowmeters are used in numerous branches of industry to measure the volume flow of liquids, gases and steam.

Applications in the chemicals and petrochemicals industries, for example, in power generation and heat-supply systems involve widely differing fluids: saturated steam, superheated steam, compressed air, nitrogen, liquefied gases, flue gases, carbon dioxide, fully demineralized water, solvents, heat-transfer oils, boiler feedwater, condensate, etc.

Read MoreDifferential Pressure Flowmeters

Continuous level, flow and differential pressure measurement Differential pressure transmitters with piezoresistive pressure sensors and welded metallic membrane or electronic dp or diaphragm seal is used mostly in the process industry.

Deltabar offers continuous level measurement in liquids as well as volume or mass flow measurement using primary elements. It is also possible to do filter monitoring with the differential pressure transmitter. .

Read MoreThermal Mass Flowmeters

Thermal meters: For direct mass measurement of industrial gases, compressed air and aqueous fluids

Whenever high turndown or low pressure losses are important in gas metering applications in any industry, thermal mass flowmeters offer a real alternative to traditional measuring techniques – whether for process control, consumption and supply monitoring, detecting leaks or monitoring distribution networks. .

Using insertion versions, it is also possible to measure gas flows in very large pipelines or in rectangular ducts.

Read MoreHigh Precision Non-invasive Flowmeters

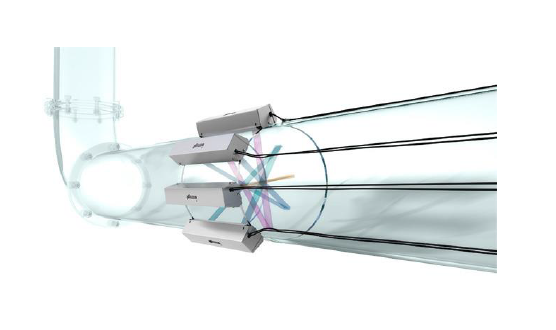

The FLUXUS F/G706 combines highest precision with the advantages of non-invasive ultrasonic liquid & gas flow measurement.

With its 4 beams, in reflect mode providing 8 paths through the gaseous medium, the meter averages the result of up to 4 planes. This arrangement averages out cross-flow profile disturbances and achieves the optimum non-invasive compensation. On longer straight runs, the 4-Beam meter achieves outstanding accuracy performance due to the individually averaged path effects and can thus be used forredundancy measurements of custody transfer meters or leak detection.

Read MoreNon-invasive Flow Measurement at Extreme Temperatures

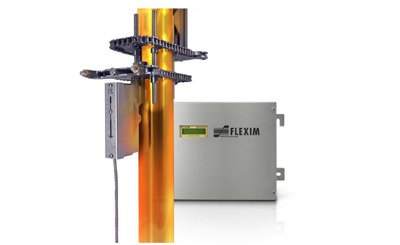

WaveInjector-Non-invasive Flow Metering at extreme temperatures from -40 °C up to 600 °C.

Using patented technology, the WaveInjector thermally separates the ultrasonic transducers from the hot or cryogenic pipe, allowing permanent flow measurements at extreme pipe wall temperatures.

*Special solutions for temperatures of max. 600 °C possible

*Special solutions for temperatures of min. -200 °C possible

Non-invasive Flowmeter for LNG and Cryogenic Fluids

The superior measuring solution for cryogenic fluids Since 2008 FLEXIM’s unique non-invasive ultrasonic flow meters have been running in various LNG applications: from 3” lines in peak shaving plants to 36” pipes for tanker off-loading to storage tanks.

The non-invasive ultrasonic meters provide a solution for all cases where reliable and trouble-free flow measurement is required. The ultrasonic measurement with its huge turndown is ideally suited to cover the highest flow rates of loading / off-loading processes as well as very low flow rates at start or stopofoperation. The measuring accuracy meets all monitoring, control and SIS purposes. Implemented diagnostics can be used to detect beginning and end of the liquid flow in batch processing.

Read MoreOnline Process Analysers

Flexim PIOX process analysers measure the Concentration, density and mass flow rate either non-intrusively by ultrasonic of via refractometry. especially aggressive, corrosive and toxic media are not a challenge for an accurate and reliable real time monitoring with PIOX

ULTRASONIC FLARE/VENT FLOWMETERS

Fluenta is a world leader in ultrasonic flare gas measurement with a mission to empower the oil and gas industry to stay at the forefront of legal and environmental compliance through accurate measurement, unrivalled temperature-handling capabilities, and ultrasonic sensing innovations.

Fluenta's sole focus and dedication to flare gas measurement since 1985 enables it to design and deploy robust solutions for the industry's most challenging applications and conditions.

Turbine Flow Meters

The turbine meter is an indirect volume meter. It essentially consists of a freely rotating axial turbine wheel in a liquid flow. The turbine wheel is rotated by the liquid and spins at a rotational speed, which corresponds to the average flow velocity of the liquid in the free cross section of the turbine flow meter. The rotational speed of the turbine wheel is thus proportional to the volumetric flow and the number of revolutions is proportional to the volume, which flows through.

Read MoreOval Gear Meters

Oval gear meters are direct volume meters. The measuring element of an oval gear meter consists of two toothed precision oval wheels, which are driven by the liquid and roll around each revolution of the oval wheel pair. The number of revolutions is an exact measure of the quantity, which flows through.

Read MoreFlow Computing and Automation

A range of wired and wireless flow computers with embedded control that provide the hub of a digital wellsite enabling operators to realize savings from rapid, low-cost wellsite deployment and deliver high integrity real-time data.

Read More